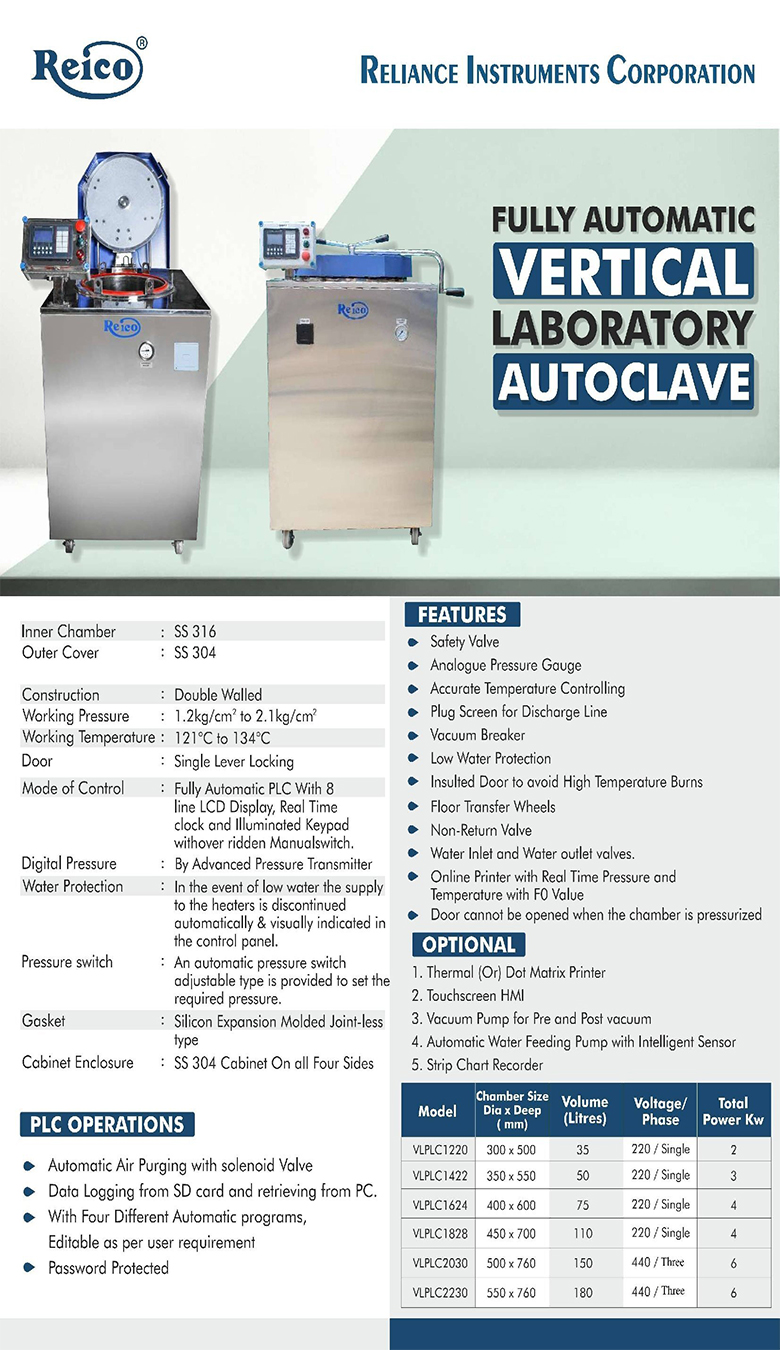

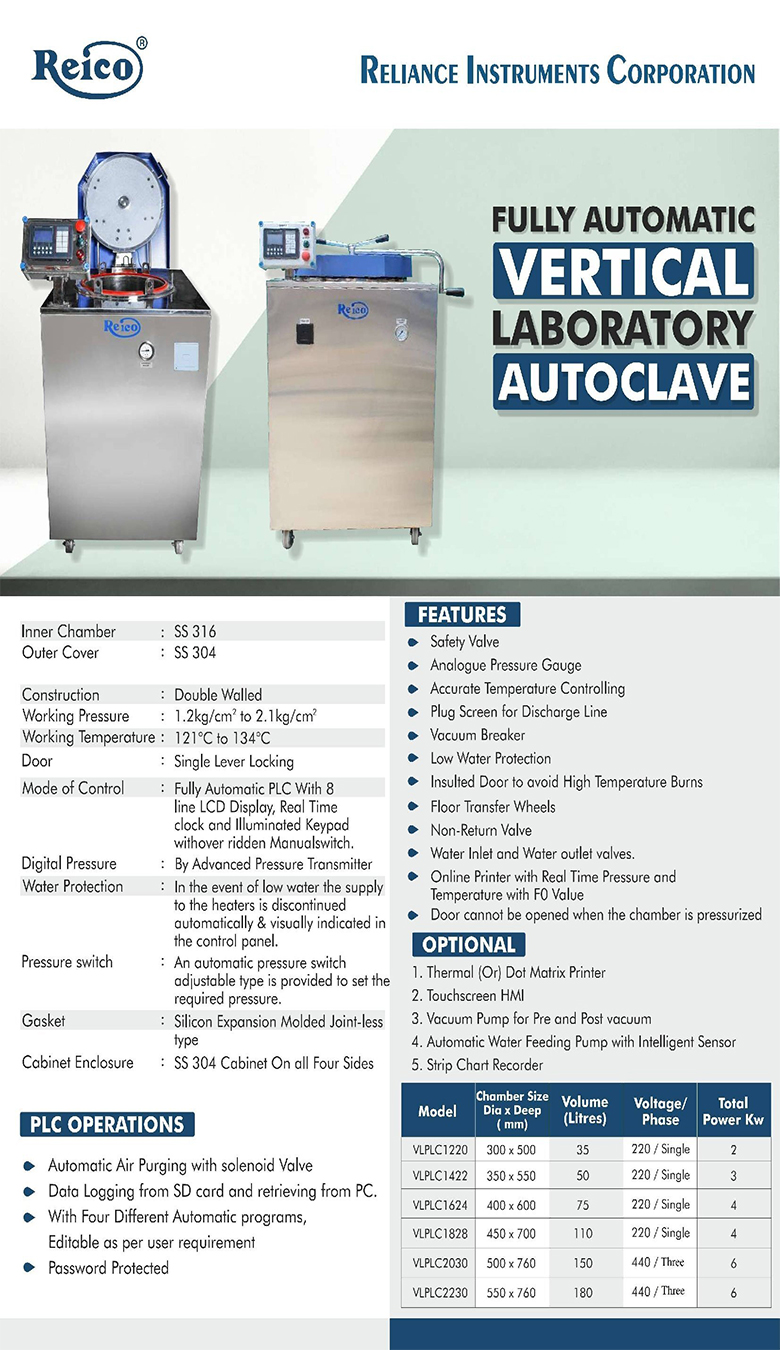

VERTICAL AUTOCLAVE/ STEAM STERILIZER

Vertical Autoclave Manufacturers in Chennai

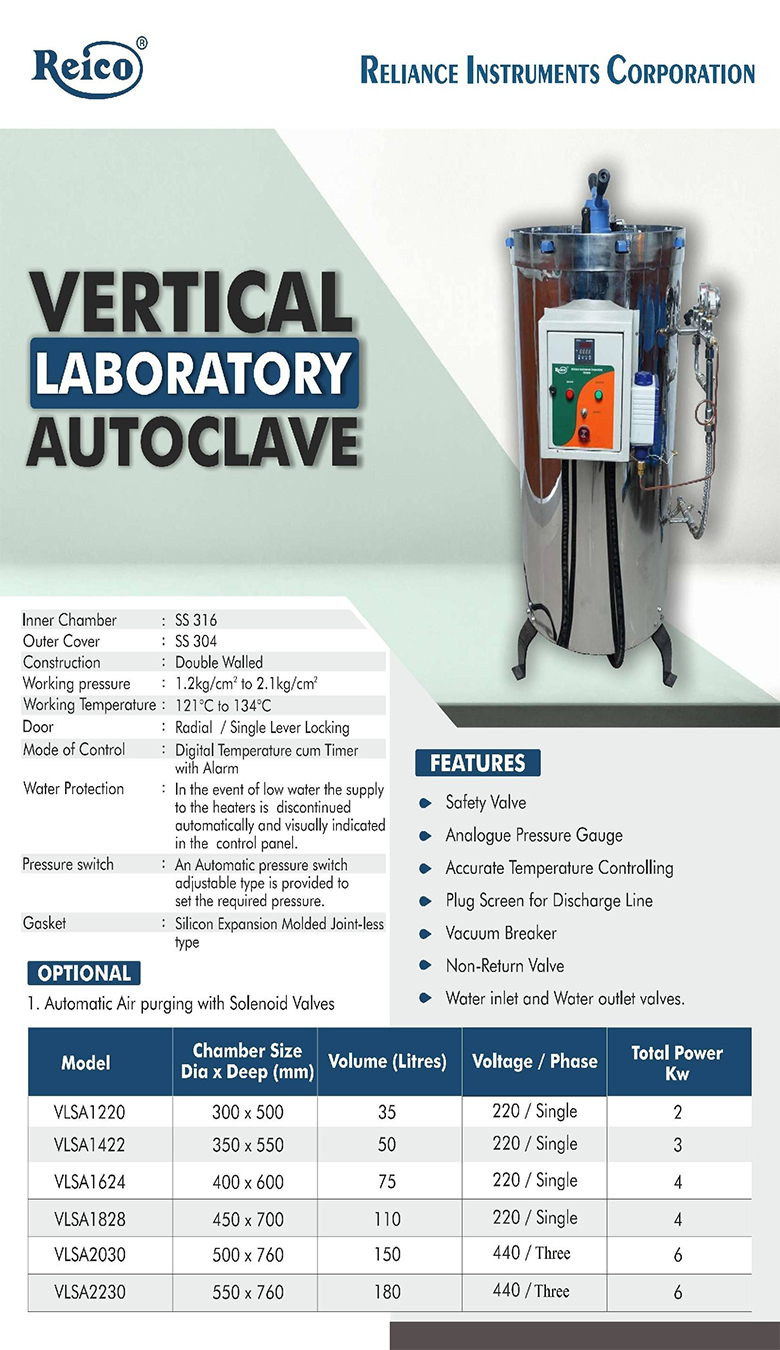

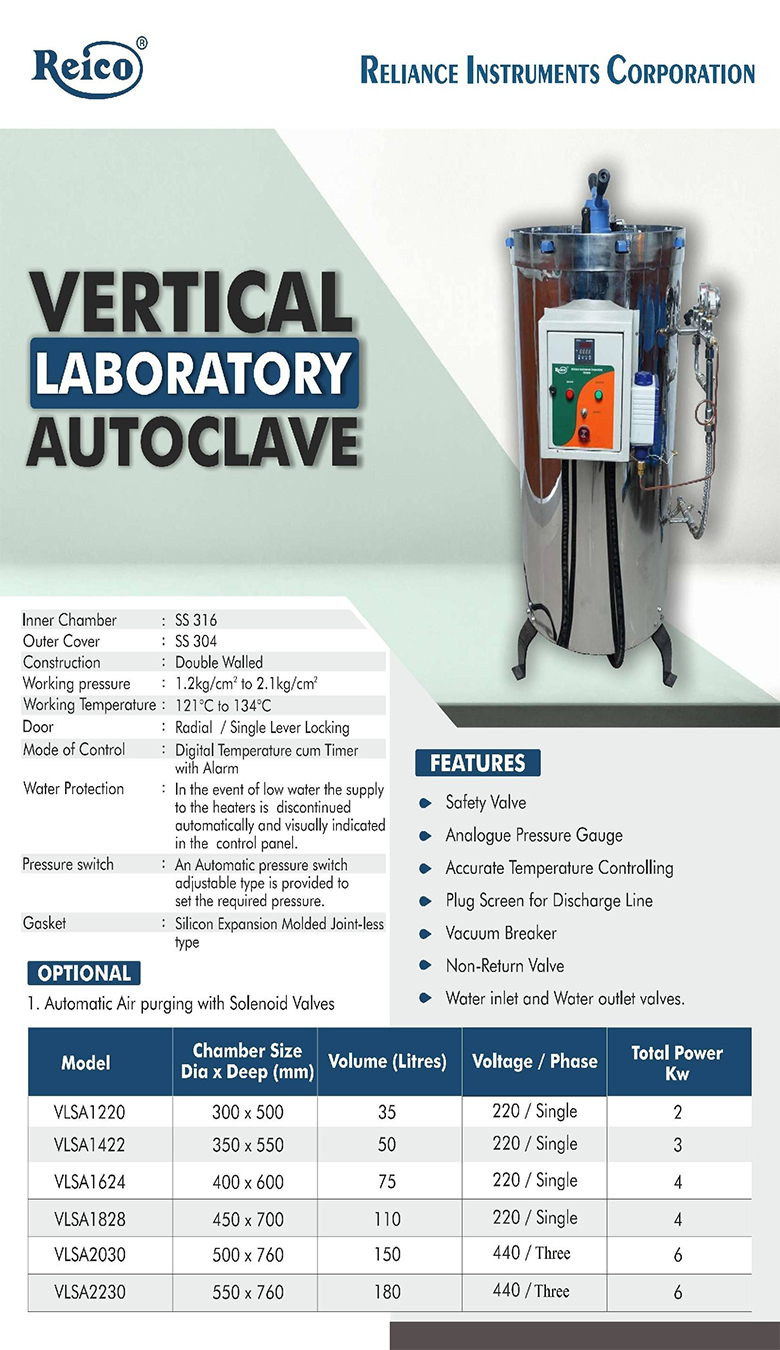

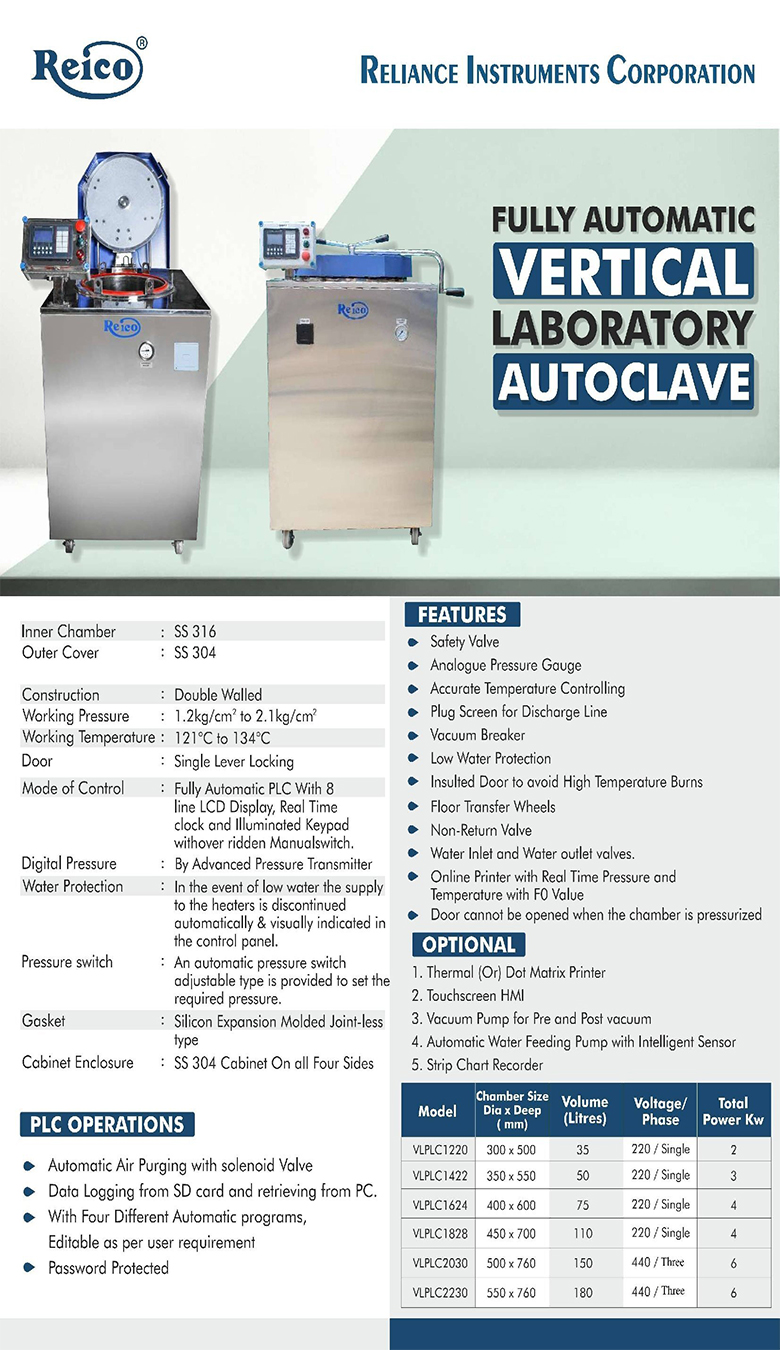

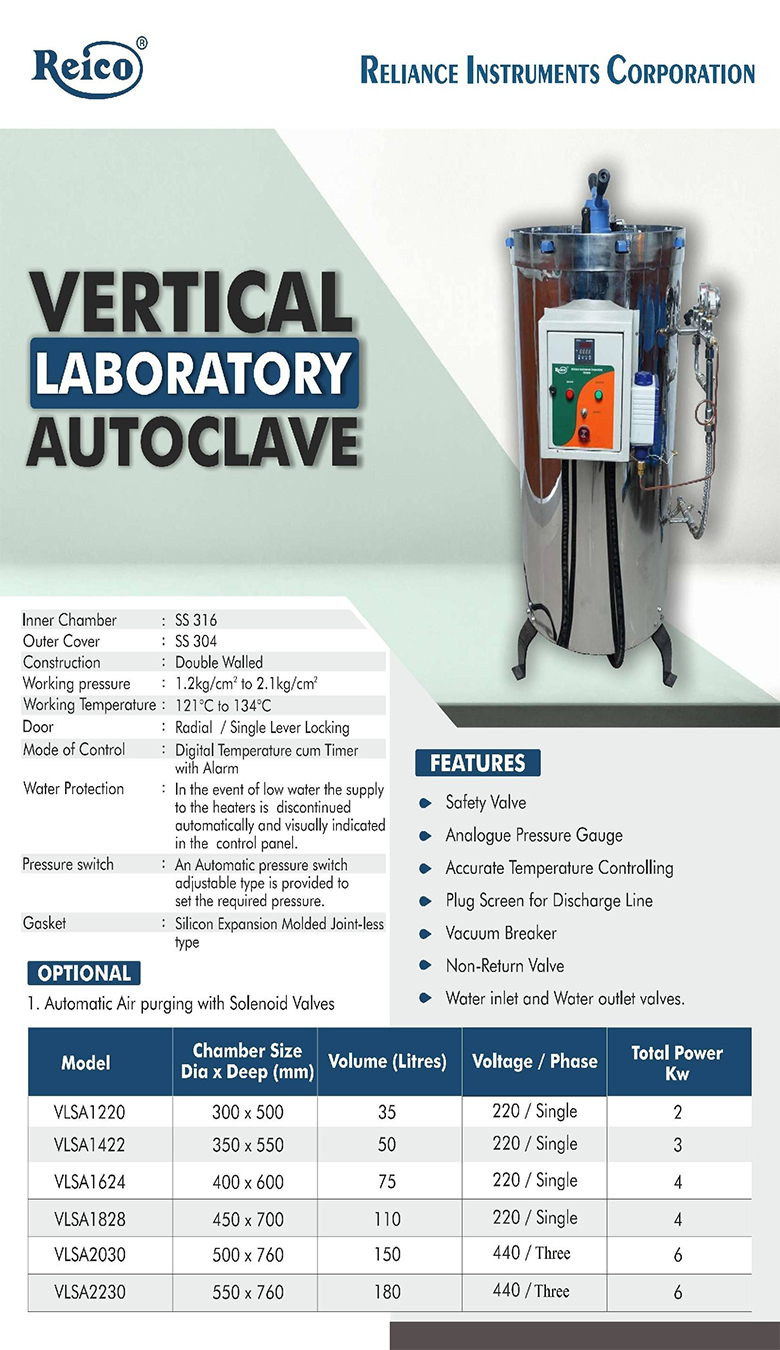

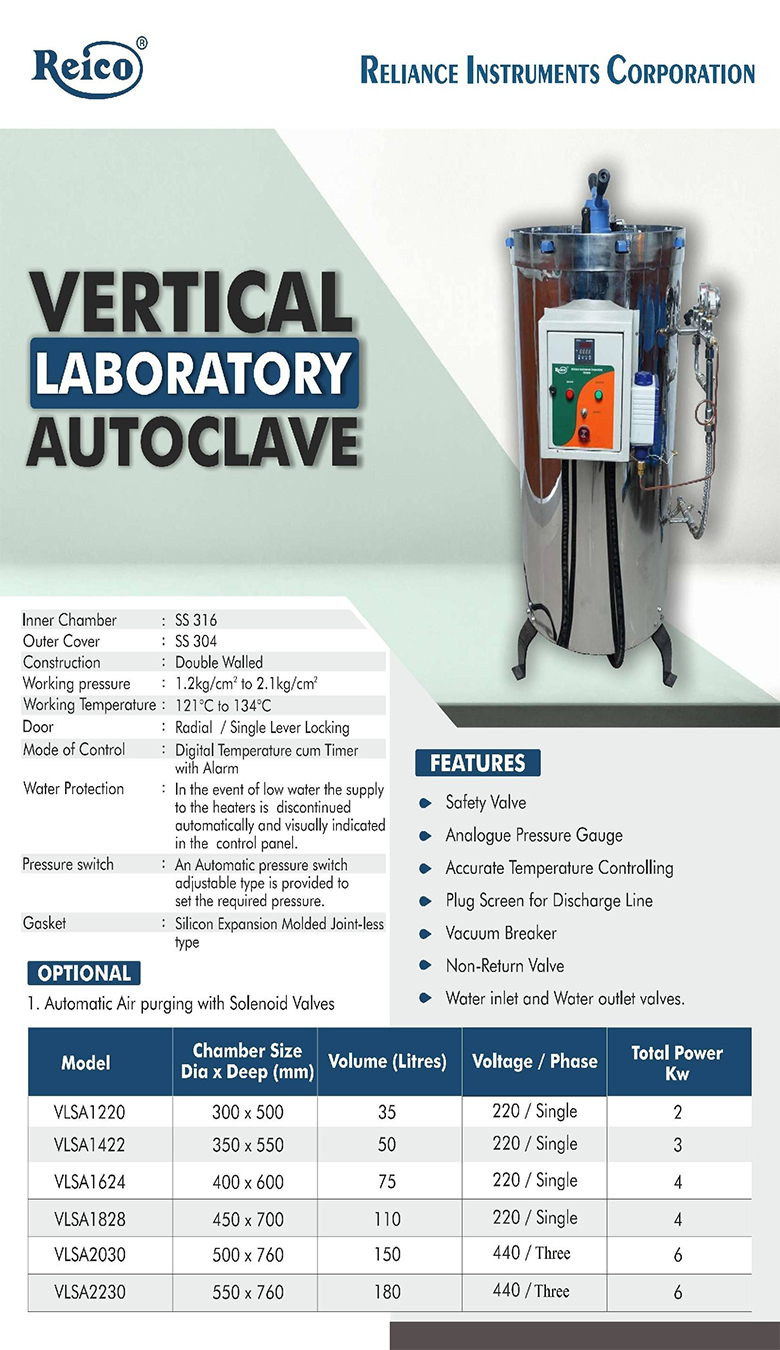

Vertical autoclaves are also called top loading sanitizers that come in round and cylindrical shape. These are widely utilized in hospitals, Operation Theater (OT), research facility for cleansing of different average and cultures. The working of vertical autoclave is easy to understand; to open, a radial locking component is fitted at top of the cover; a foot switch (pedal) is attached at the base.

Vertical Autoclave Manufacturers in Tamil Nadu

Vertical autoclave, also called steam sanitizers and top loading sanitizers, is a sterilizing machine that arrives in a round and cylindrical shape. These machines help in sanitization of medical equipment, surgical instruments to give some examples. Disinfection is one of the vital clinical cycles in numerous businesses including food and healthcare.

Vertical Autoclave Manufacturers in Coimbatore

The vertical autoclave works away at the standard of high-tension for sterilizing equipment and medical apparatuses. The essential capability of top loading or vertical autoclaves is to produce steam for making strain and developing intensity. The formation of intensity assists in cleaning medical apparatuses with loving jars, measuring beakers, and so on, and makes them free from infections, microbes, and different microorganisms.

Vertical Autoclave Manufacturers in Mumbai

The standard fittings of an vertical autoclave comprise programmed pressure switch, pedal lifting device, steam release valve, water outlet valve, low water marker, safety valve, heating light, and so on. No matter what the type and construction of an autoclave, these parts are available and carry out individual function.

Vertical Autoclave Manufacturers in Kolkata

On account of a simple vertical autoclave, there can be a deformity in the pressure regulating valve. The spring inside the valve can lose its flexibility. Likewise, there can be a blockage inside the valve. on the other hand, the valve can go through blockage because of storage for a more drawn out timeframe, rusting, and so on. In the above cases, the valve won't work as expected.

Vertical Autoclave Manufacturers in Delhi

Particularly dedicated to provide the quality designing solution for its clients; we are pioneer in planning and creating extensive range of standard and redone models of vertical autoclaves for the everyday cleansing cycle in various lab applications. Sanitizers are planned to deal with the sterilization set up that assistants in dispensing with/executing all signs of microbial life.

Vertical Autoclave Manufacturers Chennai

The Vertical Autoclave are air insulated from inside. It very well may be integrated with mineral glass fleece protection on customers' demand. Thick steel plate fixed with stainless steel sheet of SS 304 grade with locking course of action makes up the cover of the system. It guarantees simple and smooth opening And shutting activity of the autoclave.

Vertical Autoclave Manufacturers Tamil Nadu

A vertical autoclave can be referred to as a 'top loading autoclave', as the chamber door turns upwards to allow admittance to the chamber beneath. We delivers four unique sizes of this type going from 63 liters in limit up to 135 liters. All are fitted with castor wheels as standard making them simple to move, and more 'compact' than the frequently bulkier horizontal chamber units.

Vertical Autoclave Manufacturers Coimbatore

It is possible to sanitize a wide variety of burdens in both flat and vertical autoclaves with chosen choices fitted to them. In everything except the littlest chamber sizes it is typically conceivable to add a vital steam generator for more effective steam creation, and a heated coat and high level vacuum for upgraded drying of permeable or blended dispose of loads.

Vertical Autoclave Manufacturers Mumbai

The door locking system on this vertical autoclave, is temperature dependent and sticks to public and worldwide safety norms. The door remains locked for however long there is abundance strain in the chamber. The cover, as different pieces of the pressure vessel and lodging, is made of stainless steel. The advanced plan faceplate, which likewise contains the control panel, show and part of the control technology,

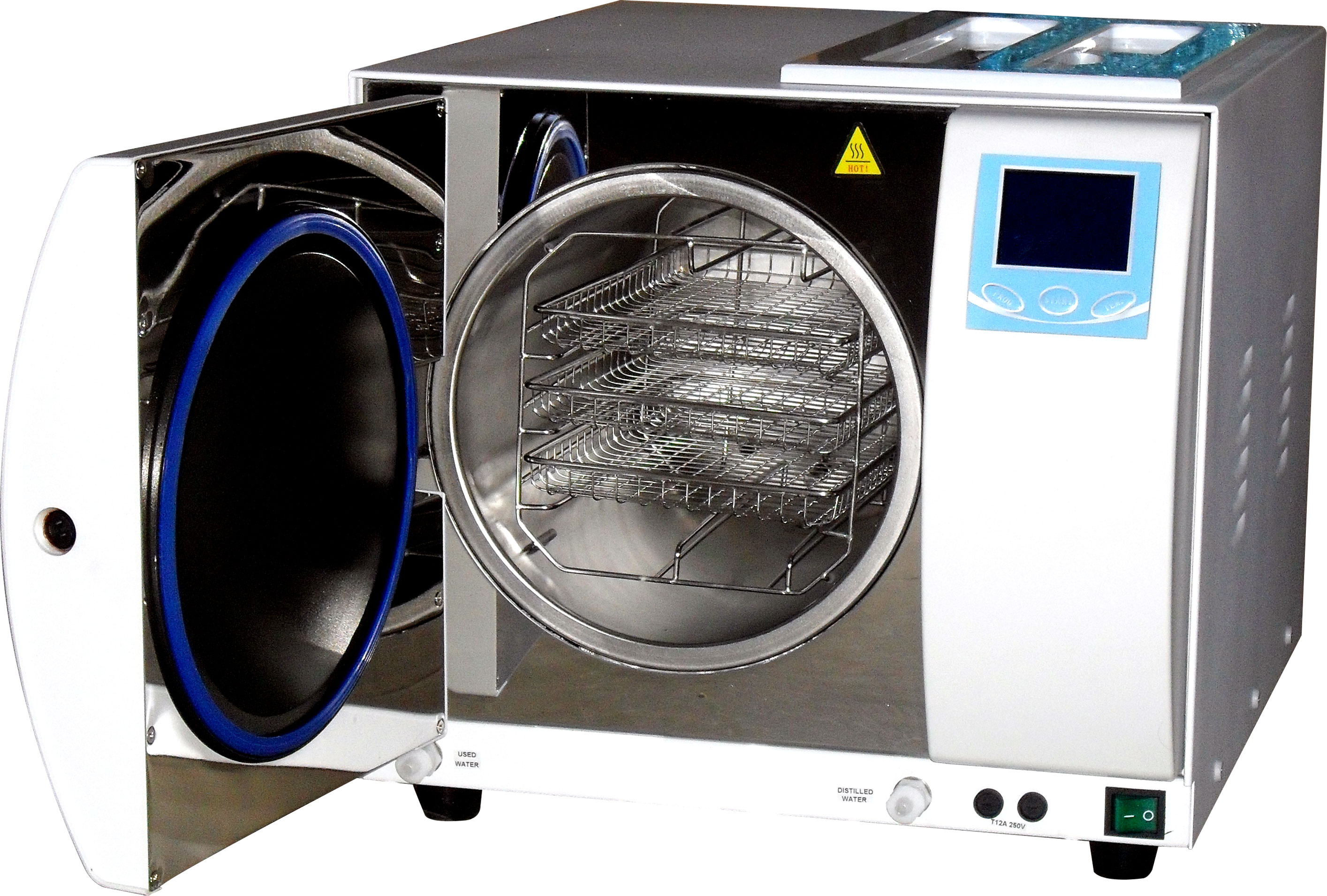

Steam Sterilizer Manufacturers in Chennai

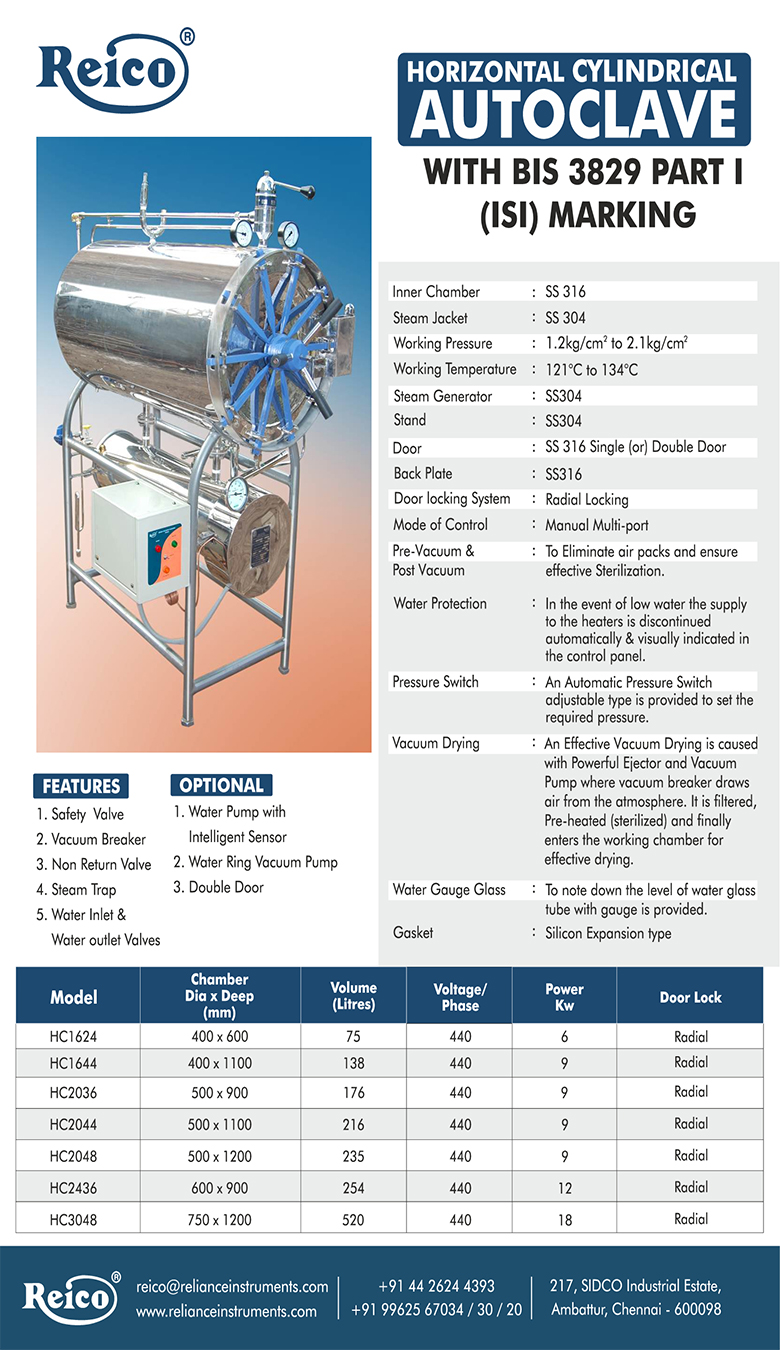

The fundamental guideline of steam sterilization, as achieved in an autoclave, is to open everything to coordinate steam contact at the expected temperature and pressure for the predefined time. Along these lines, there are four boundaries of steam sterilization: steam, pressure, temperature, and time. The ideal steam for sterilization is dry immersed steam and entrained water 813, 819 Pressure fills in as a way to get the high temperatures important to kill microorganisms rapidly.

Steam Sterilizer Manufacturers in Tamil Nadu

Specific temperatures should be acquired to guarantee the microbicidal movement. The two normal steam-sterilization temperatures are 121°C (250°F) and 132°C (270°F). These temperatures (and other high temperatures) should be maintained for an insignificant time frame to kill microorganisms. Perceived least openness periods for disinfection of wrapped medical care supplies are 30 minutes at 121°C (250°F) in a gravity dislodging sanitizer or 4 minutes at 132°C (270°F) in a prevacuum sanitizer (Table 7).

Steam Sterilizer Manufacturers in Coimbatore

The two essential sorts of steam sterilizers (autoclaves) are the gravity displacement autoclave and the rapid speed sterilizer. In the previous, steam is conceded at the top or the sides of the disinfecting chamber and, on the grounds that the steam is lighter than air, powers air out the lower part of the chamber through the drain vent.

Steam Sterilizer Manufacturers in Mumbai

The test is utilized every day the vacuum-type steam sanitizer is utilized, before the principal processed load. Air that isn't taken out from the chamber will obstruct steam contact. More modest dispensable test packs have been conceived to replace the heap of collapsed careful towels for testing the viability of the vacuum framework in a prevacuum sterilizer.

Steam Sterilizer Manufacturers in Kolkata

One more plan in steam sterilization is a steam flush-pressure pulsing process, which eliminates air quickly by over and over rotating a steam flush and a pressure heartbeat above environmental pressure. Air is quickly eliminated from the load as with the prevacuum sterilizer; however air spills don't influence this cycle in light of the fact that the steam in the cleaning chamber is consistently above atmospheric pressure.

Steam Sterilizer Manufacturers in Delhi

Like other sterilization systems, the steam cycle is observed by mechanical, chemical, and organic screens. Steam sterilizers as a rule are checked utilizing a printout (or graphically) by estimating temperature, the time at the temperature, and pressure. Regularly, chemical indicators are appended to the outside and integrated into the pack to screen the temperature or time and temperature.