To Know about

Our Products

Who We Are?

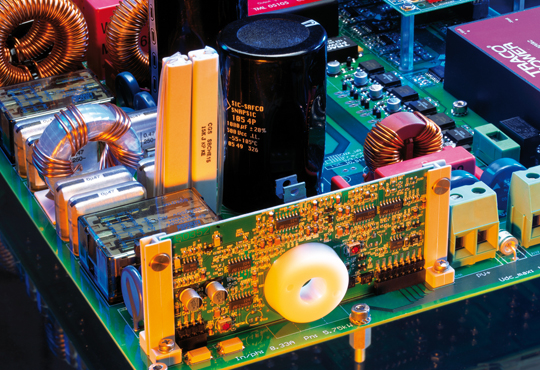

Reliance Instruments Corporation is a heterogeneous organization involved in manufacturing of sterilizing, disposing of biomedical waste and water distillation(multi column distillation).

Incorporate latest technology in above fields. Other areas CGMP validation, process automation and consultation on turnkey basis for setting of CSSD.The company gained wast experience in metallurgy and welding technology which involves using of latest welding automation. The manufacturing division is well equipped under one roof for instrumentation, mechanical, press components and heat transfer components above all our electrical testing laboratory is approval by bureau of standard, 30 years old company.

Read more Contact Us

Our Mission

Acting as one motivated and targeted team

Our vision

Leading medium-sized group for inductive components

Management policy

Reliance Instruments Corporation defines our aims, corporate values

Why Choose Us?

Reliance Instruments Corporation is a heterogeneous organization involved in manufacturing of sterilizing, disposing of biomedical waste and water distillation(multi column distillation). Incorporate latest technology in above fields.

1967 Grundt KG, Schwandorf, Germany Beginning of the transformer production as family business

1984 Reliance Instruments Corporation GmbH, Nabburg, Germany Foundation of the own company

1996 Expansion of the production plant

1996 Certification according to ISO 9001

2002 Foundation Reliance Instruments Corporation

2005 Foundation Reliance Instruments Corporation

2008 new plants in Germany and India Expansion of the manufactoring capacities

2009 Foundation of alttec GmbH

2011 Sycomp GmbH is integrated into Reliance firmengruppe

2014 Extension of Headquarter Nabburg

2014 Foundation of gutre GmbH

2016/2017 New building of production plant India

List Of Certification

ISO Certificate

9001:2008

13485:2003

17665-1:2006

ISI Certificate

IS 3829 Part I

IS 3829 Part II

IS 3829 Part III

CE Certificate

93/42/EC

97/23/EC

EN 285:2006+A2:2009

EN 1422: 2014

EN ISO 15883-1:2006

WHO - GMP

The management policy from Reliance Instruments Corporation defines our aims, corporate values and corporate philosophy. Our focus is being successful together with our partners (customers, employees and suppliers). We understand our aspiration for customer- and employee satisfaction, conservation of resources, constant improvement of products and environment performance, the commitment to comply with applicable legal requirements, management and monitoring because of transparency of these targets as an obligation.

Partial List of Clients

TURN KEY SOLUTION

CSSD TURNKEY SOLUTION

- Comprehensive solution for CSSD (Central Sterilization and Supply Department)

- Right Architectural planning for seamless Workflow

- Planning according to forward-moving flow, including physical barriers, promotes effective management of work procedures & reduces risk of incorrect actions by staff

- Planning confirming to international Norms

- Assures Hygiene safety and Maximum productivity

- Comprise of Planning, Installing, Staff Training and Documentation for monitoring CSSD Operations

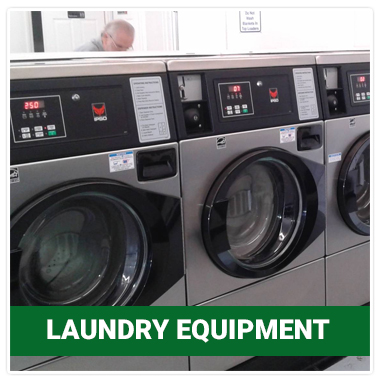

MECHANIZED LAUNDRY TURNKEY SOLUTION

- Extensive Laundry solution for Industrial, Hospital and Health Care Domain.

- Providing Architectural layout confirming NABH / MCI Norms

- Clean and Adequate quantity of washed Lenin for Uninterrupted Lenin Supply

- Safe Handling, Sorting and Separation of Soiled and Infected Linen With Efficient Water and Energy Management

- Focusing Planning, Installing, Staff training and Monitoring Mechanized Laundry

Our Services

BREAKDOWN CALLS CUSTOMER COMPLAINT